Revolutionizing Plastic Film Recycling: Exploring the Efficiency of Washing Lines

Plastic film recycling has long been a challenging endeavor due to the complexities of sorting and cleaning the material. However, the advent of washing lines has revolutionized this process, significantly enhancing efficiency and sustainability. In this article, we delve into the intricacies of washing lines, exploring how they streamline the recycling process and contribute to a greener future.

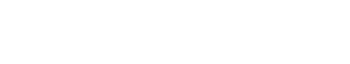

Washing lines are at the heart of modern plastic film recycling facilities, where they play a crucial role in preparing materials for reuse. These sophisticated systems are equipped with a range of technologies designed to remove contaminants, such as dirt, grease, and labels, from the plastic film. The process begins with the sorting of incoming materials, where various types of plastic film are separated based on their composition and quality.

Once sorted, the plastic film is fed into the washing line, where it undergoes a series of cleaning stages. Water and detergents are used to remove surface impurities, while mechanical scrubbers and brushes ensure thorough cleaning. Advanced filtration systems are employed to remove solid particles from the wash water, allowing it to be recycled within the system.

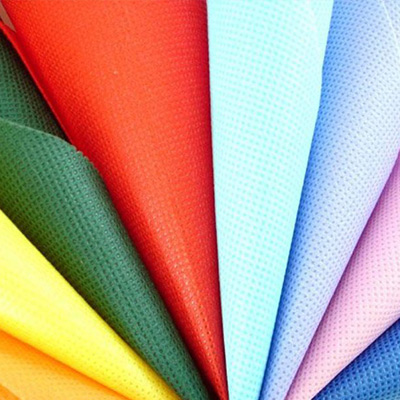

One of the key benefits of washing lines is their ability to maximize the yield of recycled materials. By effectively removing contaminants, washing lines ensure that the resulting material meets stringent quality standards. This high-quality recycled plastic can then be used in a variety of applications, including the production of new packaging, construction materials, and consumer goods.

In addition to improving material quality, washing lines also contribute to environmental sustainability. By diverting plastic film from landfills and incinerators, these systems help reduce the carbon footprint associated with waste disposal. Furthermore, the use of recycled plastic in manufacturing helps conserve natural resources and reduces the demand for virgin materials.

The efficiency of washing lines is further enhanced by continuous innovation and technological advancements. From automated sorting systems to advanced water recycling technologies, manufacturers are constantly seeking ways to improve the performance of these systems. Data analytics and artificial intelligence are also being integrated into washing lines to optimize operation and minimize energy consumption.

In conclusion, washing lines are transforming the landscape of plastic film recycling, making the process more efficient, sustainable, and economically viable. By removing contaminants and maximizing material yield, these systems play a crucial role in closing the loop on plastic waste. As we continue to innovate and improve upon existing technologies, washing lines will undoubtedly remain a cornerstone of the recycling industry for years to come.