ONE STOP TURN WASTE INTO PELLETS

Drip Irrigation Tape Recycling Machine

Irrigation drip tape recycling line can treat with agriculture drip tape efficiency. The whole process include crushing, water rinsing, friction washing, dring by washing system; plasticization, pelletizing and drying by pelletizing system. PLC intelligent system realized high automatic, the whole line just need 3-4 man to operate. With 25 years of experience in recycling, KITECH not only mastered the key technology, but also improved machine designs to address specific product features. KITECH offers drip tape recycling solutions that are high output and low energy consumption.

Know how

Provide

turnkey

Recycle more

WASHING PROCESS

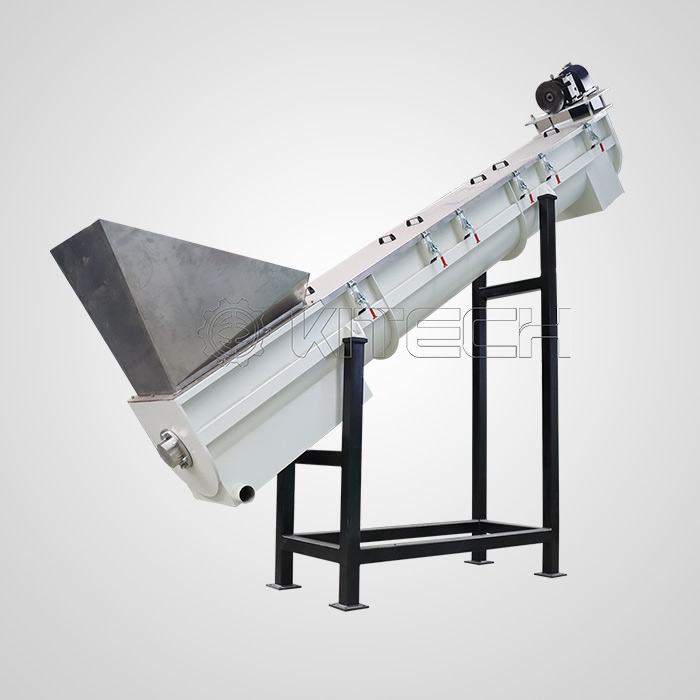

Belt conveyor

Heavy duty type, adopt gear motor; Side walls to avoid spilling of feeding material;

Crusher

Optimally designed blades are sharp and powerful; Enclosed cutting chamber to prevent materials flying out; Knives are externally adjustable;

Screw conveyor

Screw adopt wear resistant stainless steel; Triple sealing, External bearing design;

Washing tank

Double station discharge valve at bottom; All Thumb-wheel speed variable by inverter control; Heavy duty washing, separation of different specific densities material;

friction washer

Rotor and blades adopt wear resistant steel; Rotor with dynamic balance treatment. Accuracy: ±3-5g; Active material washing to protect downstream units;

Centrifugal dryer

Rotor with dynamic balance treatment. Accuracy: ±3-5g; Mild circular screen in polygon 4 piece version; Washer/dryer housing built in stainless steel welded construction;

Hot air pipe dryer

Pipeline built in stainless steel welded construction; All part touch raw materials are stainless steel; Hot air drying system;

Electrical cabinet

International brand Low voltage components ; Double circuit safety relay; Intelligent and modular PLC controlling system.

PELLETIZING PROCESS

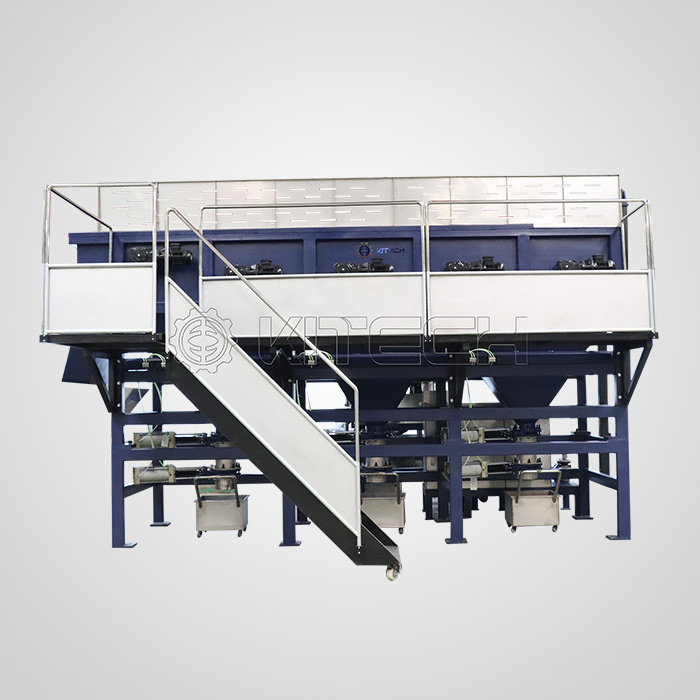

Feeding

Belt conveyor for plastic scrap feedingl automatically, Feeding speed adjustable by inverter controller according to the feeding amount.

Compating

The plastic material got cutting, mixing and preheating in compactor uniformly, to ensure the material heated and dried effectively

Extrusion

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one.

Degassing

Force double vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output pellets.

Filtration

Plate type, piston type, back flush type and automatic self-cleaning type filter, you have different choice according to impurity contents in material and your habit.

Pelletizing

New European design water ring pelletizer, Cutting speed of pelletizer controlled automatically by PLC according to the pressure of die head, which could achieve the uniform size for output pellets.

Drying

Vibration dryer combined with horizontal type centrifugal dryer to get well dried final granules.

Controlling

Thanks to Siemens PLC and HMI, KCP series recycling pelletizing machine provides high intelligent operation system which is easy to operate and save manpower.

TECHNICAL DATA

| Technical parameter | ||||

| Capacity(kg/h) | 500 | 1000 | 2000 | |

| Energy consumption(KWH) | 119+173 | 165+315 | 209+315+315 | |

| Dimension | Depends on factory layout | Depends on factory layout | Depends on factory layout | |

| Washing Process | ||||

| Belt conveyor | Belt width(mm) | 600 | 800 | 800 |

| Motor power(KW) | 2.2 | 3 | 3 | |

| Crusher | Grind chamber(mm) |

500*700 | 700*1000 | 700*1200 |

Motor power(KW) |

55 | 75 | 90 | |

| Screw conveyor | Screw diameter(mm) | 250 | 300 | 400 |

| Washing tank | Dimension of tank(mm) | 5000×1200 | 6000×1600 | 8000×1800 |

| No. of thumb-wheel(pcs) | 5 | 6 | 8 | |

| Screw conveyor | Screw diameter(mm) | 250 | 300 | 400 |

| Friction washer | Screw diameter(mm) | 300 | 400 | 450 |

| Centrifugal dryer | Rotor diameter(mm) | 460 | 500 | 550 |

| Hot air pipe dryer | Pipe diameter(mm) | 133 | 159 | 169 |

| High-speed hot cleaning | ||||

| Color sorter | ||||

| Storage buffer | Storage capacity(CBM) |

3 | 4 | 6 |

| Pelletizing Process | ||||

| Type | KSP120 | KSP180 | kSP180*2 | |

| Belt conveyor | Belt width(mm) |

600 | 800 | 800 |

Motor power(KW) |

1.5 | 2.2 | 2.2 | |

| Extruder | Screw diameter (MM) |

Φ120 | Φ180 | Φ180 |

L/D |

25-35 | 25-35 | 25-35 | |

Motor power (KW) |

132-160 | 250-315 | 250-315 | |

| Filter | Two position plate type |

|||

| (options) | Two position piston type |

|||

Back flush piston type |

||||

Automatic self-cleaning type |

||||

| 2nd Extruder (Optional) | Screw diameter (MM) |

Φ150 | Φ180 | Φ180 |

L/D |

10-18 | 10-18 | 10-18 | |

Motor power (KW) |

45-55 | 75-90 | 75-90 | |

| Downstream (options) | Water ring pelletizer |

|||

Strand pelletizer |

||||

Automatic strand pelletizer |

||||

Underwater pelletizer |

||||

| Electrical cabinet | ||||

| PLC controller | ||||

| Man power(person/shift) | 3-4 | 4-5 | 5-6 | |

| Delivery time(days) | 60-70 | 70-80 | 80-90 | |

| Warranty(months) | 13 | 13 | 13 | |

| Standard | Alternative |